The Art of Making Silk

Just outside Siem Reap is a silk farm, where for free, you can go on a tour and see the whole process. They will even give you a free ride on their shuttle bus. Yes, they have a gift shop at the end, a very lovely one, but there is absolutely no pressure to buy anything, although you might be tempted to! And it’s nice to tip your tour guide. I was amazed at what it takes to go from a worm to a single piece of fabric. I think you will be too!

It all starts here, with mulberry leaves. A mulberry leaf diet creates the finest silk.

In the beginning, tiny worms hatch from eggs, like little brown grains of rice…

…which then grow bigger and bigger, as they feast on juicy green mulberry leaves.

Eventually, they are big enough to start creating their cocoons, which are basically made from worm saliva. I know, kind of yuck! What’s amazing is that they spew out one long single strand, about a kilometer long.

The cocoons are then put into specially made baskets, until it’s about time for them to hatch, and then…

…20% are allowed to break out of their cocoon for reproductive purposes, but the other 80% of the cocoons are spread out in the sun, which sadly, kills the moth inside. If they are allowed to break the cocoon, the silk thread is no good, as it is broken.

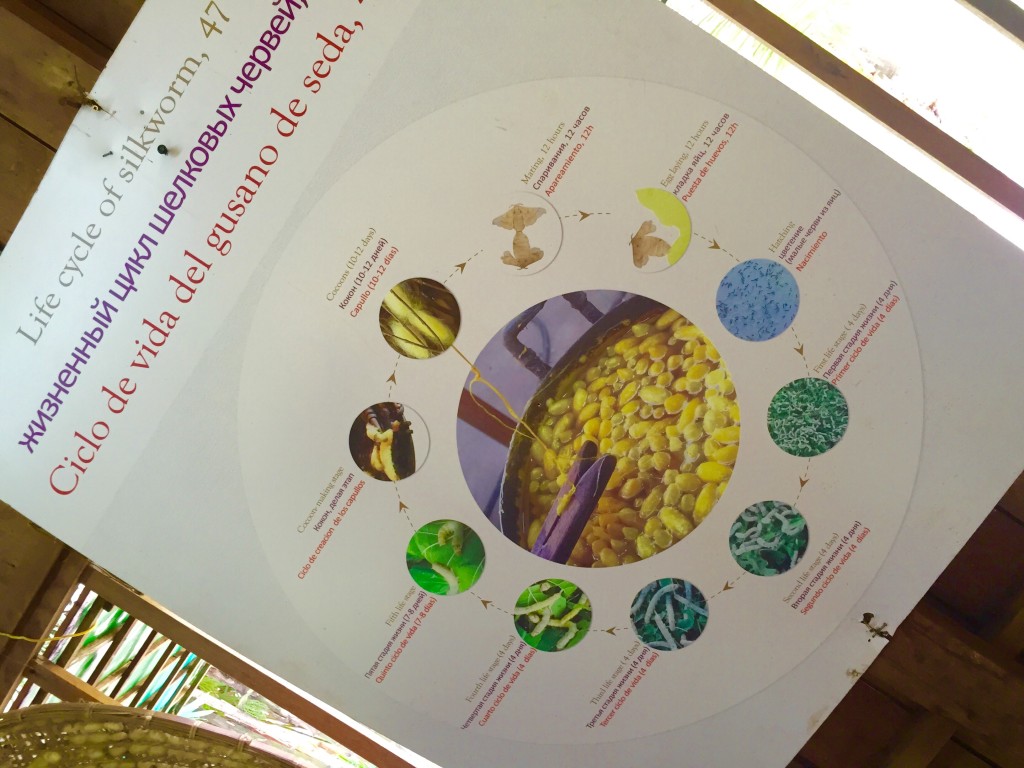

The life cycle of a silk worm is 47 days (note that the mating cycle is 12 hours – no wonder the males die off right after!)

Next, the cocoons are brought inside, where they are boiled. This allows for the individual long fibers to be carefully unwound and fed into the spinning reel, usually from 4-8 cocoons at once.

It takes bout 2500 silkworms to produce a pound of silk, which represents about 1000 miles of filament.

Silk threads are spun…

…and little pieces of cocoon are picked out by hand.

There is both raw silk from the outside of the cocoon, which has a rougher texture, and fine silk from the thread inside. The fine silk is more expensive.

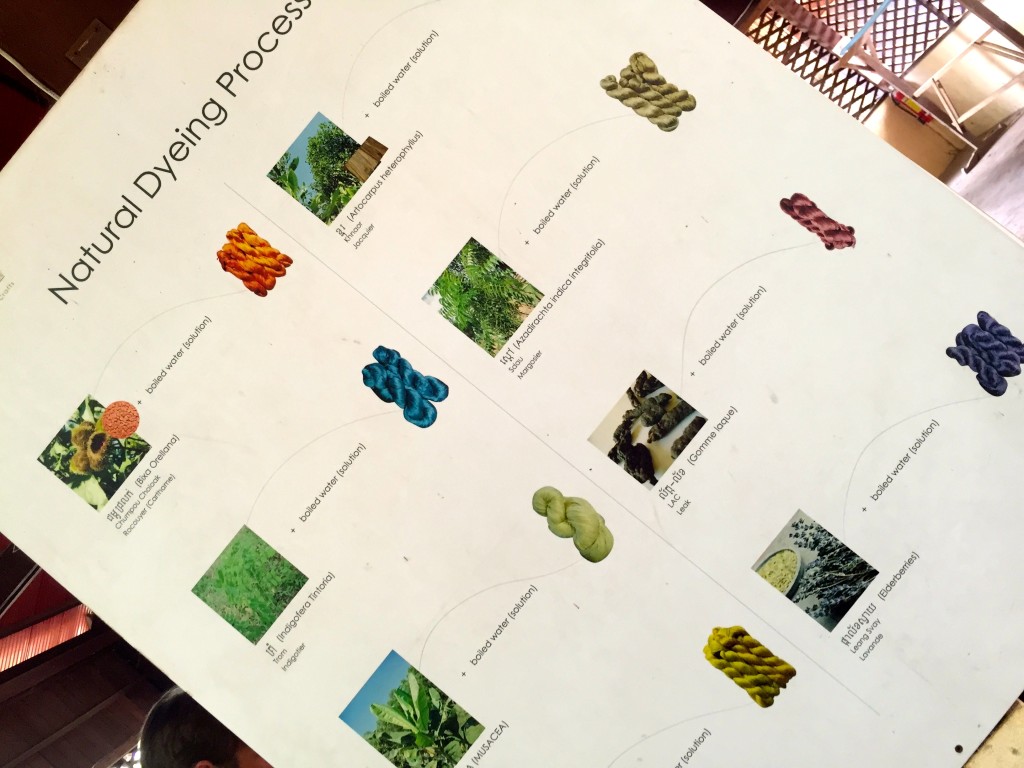

The silk thread is then dyed using various leaves, flowers, bark and other natural ingredients…

…at very high temperatures!

Then after it is dry, it is put onto spools. It gets its shimmery appearance from the triangular prism-like shape of the fiber, which allows the cloth to refract the incoming light at different angles.

Now it’s time to head to the weaving workshop…

…where first the patterns are put into place, piece by piece by hand.

And then the weaving starts!

The patterned pieces take a really, really long time…

…while the solid colors go much faster.

Some women hand roll the silk ends of threads of scarves on their legs to tie them off.

At the end of the tour, you are escorted into a silk museum, where you can see all different types of beautiful fabrics…

…as well as some clothing made with them.

My guide suggested that the only person to maybe wear this special cocoon piece would be Lady Gaga!

It’s a fascinating process, which gives you a whole new appreciation for why silk is so expensive, and is definitely worth a couple of hours in your day at Siem Reap.

So well written Lynn itch fantastic pictures to she the whole process. Always enjoy reading your takes/ adventures!!!

Thank you Soraya! I kind of thought maybe with your textiles background you might enjoy it

Lynn, I feel like I visited the silk farm myself. The pictures and your narrative are perfect. Thanks as always! (And I have so much more respect for my colorful silk scarves hanging in my closet.)

Wish you would’ve been along in person Beth, you would’ve loved it!

Great post!! As a weaver of fine silk and very familiar with the process, I especially enjoyed this. You documented it very well. Kudos!

Thank you, CC! I was hoping I got the details right 🙂 Wow, you weave silk?! I’m impressed